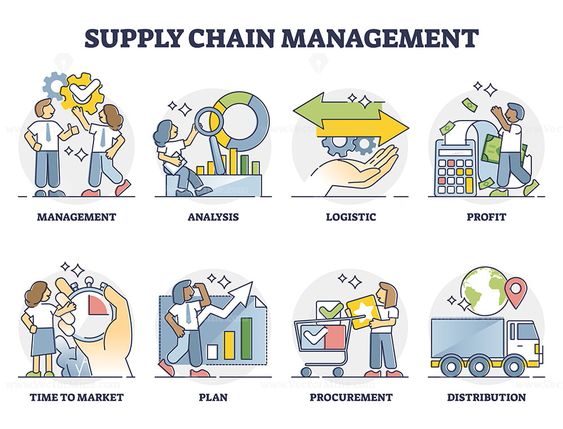

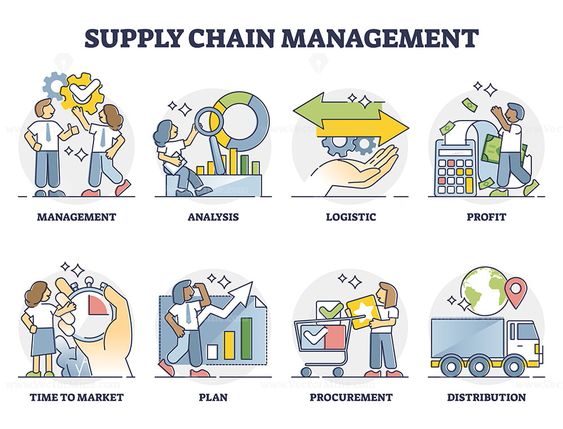

Navigating the Automotive Supply Chain Cars

In the fast-paced world of automotive car manufacturing, ensuring a steady flow of parts and components is crucial to keeping production lines running smoothly and delivering high-quality vehicles to customers. Let’s take a closer look at how manufacturers manage their supply chains, the challenges they face, and the strategies they employ to overcome them.

Coordination with Suppliers: Manufacturers work closely with a network of suppliers to procure the various parts and components needed for vehicle production. From engines and transmissions to tires and electronics, each component plays a vital role in the assembly process. To maintain a steady flow of supplies, manufacturers establish long-term contracts with suppliers, outlining specifications, quality standards, and delivery schedules. Regular communication and collaboration are key to ensuring that suppliers meet their commitments and address any issues that may arise.

Challenges in Global Supply Chains: Managing a global supply chain comes with its fair share of challenges. Manufacturers must contend with factors such as geopolitical instability, currency fluctuations, and transportation disruptions, which can impact the availability and cost of raw materials and components. Natural disasters, like earthquakes and hurricanes, can also disrupt supply chains by damaging production facilities and infrastructure. Additionally, unexpected events, such as the COVID-19 pandemic, can cause widespread supply chain disruptions, leading to shortages and delays in production.

Strategies for Optimization: To mitigate risks and optimize supply chain efficiency, manufacturers employ various strategies. One approach is to diversify their supplier base, sourcing components from multiple suppliers and geographic regions to reduce reliance on any single source. Advanced forecasting and inventory management systems help manufacturers anticipate demand and adjust production schedules accordingly, minimizing the risk of overstock or shortages. Collaborative relationships with suppliers, built on trust and transparency, enable manufacturers to work together to address challenges and find innovative solutions.

Maintaining Product Quality: In addition to ensuring a steady flow of supplies, manufacturers must also maintain product quality throughout the production process. Stringent quality control measures are implemented at every stage, from incoming inspection of raw materials to final assembly and testing. Continuous monitoring and analysis of production data help identify and address any deviations or defects promptly. Manufacturers also invest in employee training and development programs to ensure that staff are equipped with the knowledge and skills needed to uphold quality standards.

Conclusion: The automotive supply chain is a complex and dynamic ecosystem that requires careful coordination and planning to ensure smooth operations. While manufacturers face numerous challenges in managing global supply chains, they employ a variety of strategies to optimize efficiency and maintain product quality. By fostering strong relationships with suppliers, leveraging technology, and prioritizing quality, manufacturers can navigate the challenges of the supply chain and deliver exceptional vehicles to customers worldwide.

Average Rating