Clutch Types: An All-Inclusive Guide

One of the most crucial components of a car’s transmission system is the clutch type, which facilitates the power transfer from the engine to the wheels. It is an essential part of both manual and automatic cars, managing the driver’s engagement and disengagement. Clutches come in a variety of forms, each intended for a particular use and class of car. Knowing the differences between the sorts can help you take better care of your car and make the appropriate decision when an update or replacement is required. Let’s examine the numerous clutch kinds and applications.

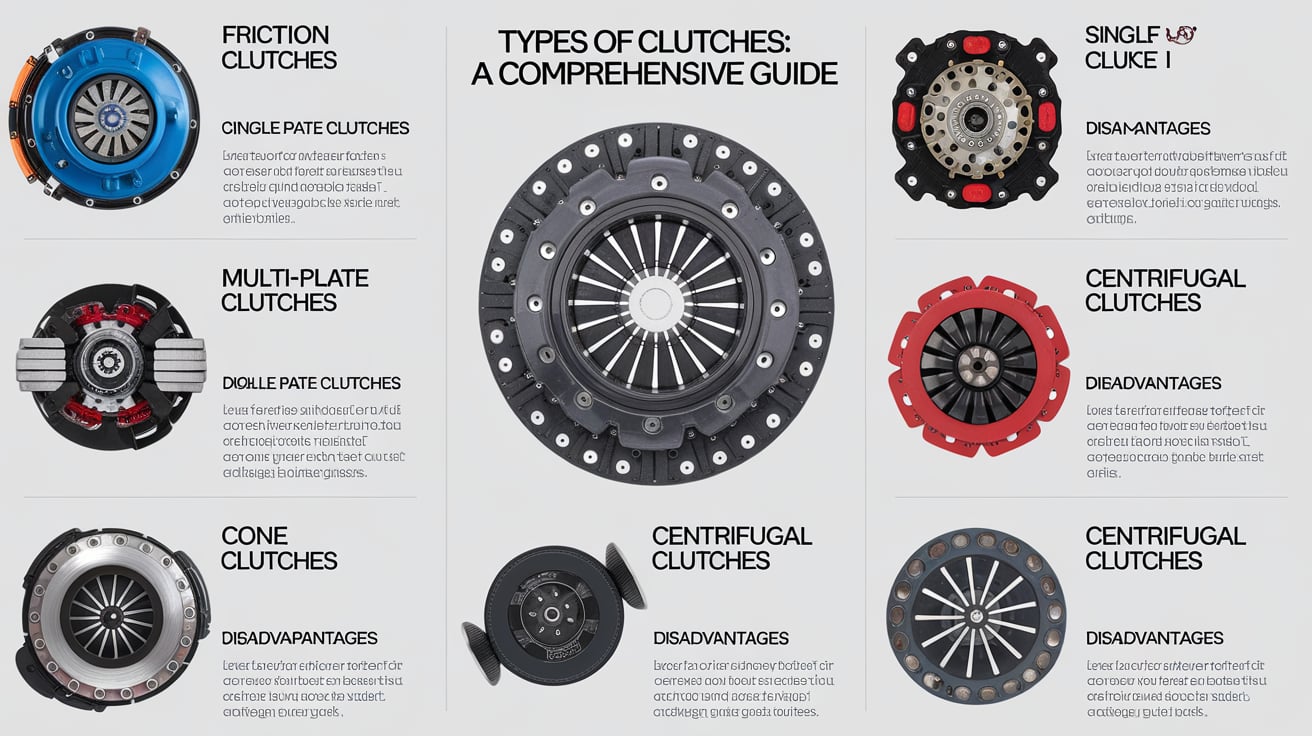

First Friction Clutch

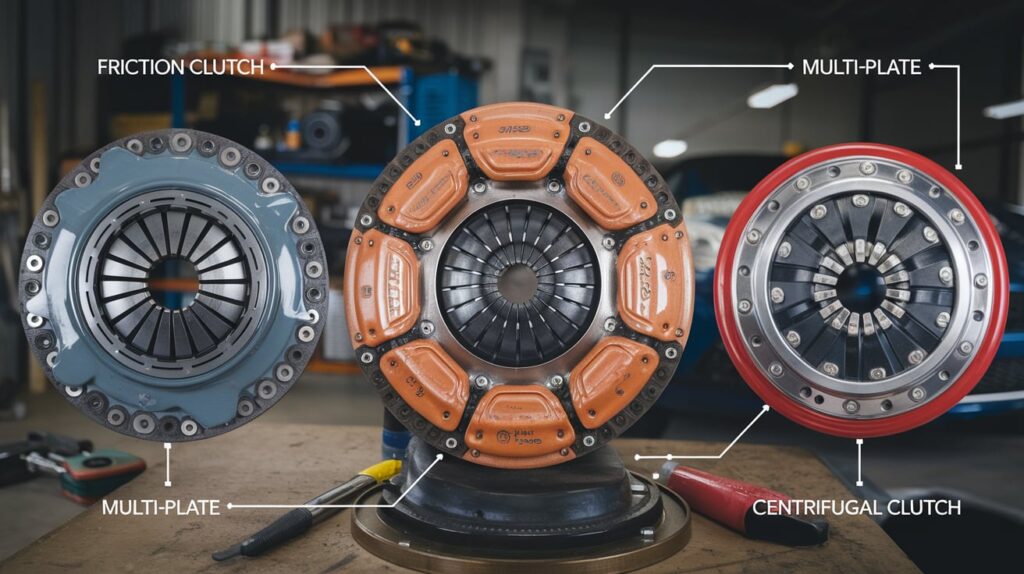

When it comes to manual transmission automobiles, the most prevalent type of clutch is the friction clutch. Power is transferred by friction between the clutch plate and the flywheel. The driver can swap gears by depressing the clutch pedal, which disengages the engine and gearbox connection.

The simplest type of friction clutch is the single-plate clutch. It is frequently seen in automobiles and other light-duty vehicles, and it consists of a single clutch plate.

Multi-Plate Clutch: By using several clutch plates, a multi-plate clutch increases the friction area. When more torque is needed, motorcycles and high-performance cars frequently choose this kind.

Cone Clutch: Conical surfaces are used for engagement in place of flat plates in the cone clutch. It is frequently utilized in cars or large machines that require a more progressive engagement.

- Clutch Centrifugal

At a specific engine speed, a centrifugal clutch engages automatically. Smaller vehicles, such as scooters, mopeds, and some motorcycles, are frequently equipped with this kind of clutch. It works on the basis of centrifugal force, which, as the engine speed increases, pulls the clutch pads outward, engaging the clutch.

Benefits: Since there is no clutch pedal to engage, centrifugal clutches are easy to use and need minimal maintenance. Because they do not need manual gear shifting, they are perfect for novices.

Cons: Because these clutches are engaged and disengaged often, particularly in stop-and-go traffic, they may wear out more quickly.

- Hydraulic Clutch A hydraulic clutch transfers force from the clutch pedal to the clutch by use of hydraulic fluid. Many contemporary cars employ this technique because it feels lighter and smoother than conventional cable-operated clutches.

Benefits: The hydraulic system offers the driver greater comfort and control since it is less labor-intensive to operate and more dependable.

Cons: Should any of the hydraulic lines or components break, repairing this system might be more difficult and costly.

- Magnetic Fastening

Electric current is used by an electromagnetic clutch to engage or disengage it. This kind is frequently seen in industrial settings, including as conveyor belts and machinery and automated transmissions. The clutch plates are drawn together by a magnetic field created when an electric current is delivered.

Benefits: Automation and remote control are possible with these clutches. Additionally, they have exact control over the process of engagement and disengagement and act quickly.

Cons: The electrical components of electromagnetic clutches may need to be maintained on a regular basis, which can be costly.

- Excessive Reliance

When the driving shaft slows down or stops, an overrunning clutch lets the driven shaft spin freely. This kind of clutch is frequently seen in some automatic gearboxes, vehicle engines as starters, and bicycles as a freewheel system.

Benefits: The driven shaft can continue to move independently of the engine speed thanks to the overrunning clutch’s effective prevention of reverse rotation.

Cons: It works best in smaller or more specialized applications and isn’t made to handle tremendous torque.

- Canine Handle

Applications where total, abrupt power engagement or disengagement without the need for friction are served by dog clutches. It is made up of teeth on the input and output shafts that lock together, or “dogs”. The teeth lock together when the clutch is engaged.

Benefits: This clutch offers a positive engagement and is utilized in applications that need for accuracy, including heavy machinery or race automobiles.

Cons: If not handled appropriately, engagement can be severe and cause wear and tear.

In summary

Essential parts of a car’s gearbox, clutches, are chosen based on the vehicle’s intended purpose, performance specifications, and design. Understanding how each type of clutch works is helpful in maintaining and enhancing vehicle performance, whether it’s the effortless functioning of a hydraulic clutch, the automation of an electromagnetic clutch, or the straightforward dependability of a friction clutch. Always contact with a skilled technician when selecting a clutch for repair or replacement to guarantee the greatest fit for your driving demands.

Internal Link: https://automotivecarindia.com/when-to-replace-a-car-abs-sensor-signs-of-a-failure/

External Link: https://testbook.com/mechanical-engineering/clutch-definition-types

Average Rating